Honouring our engineering authors and their exceptional technical papers.

A multi-technique solution for a complex design and construct project in Victoria

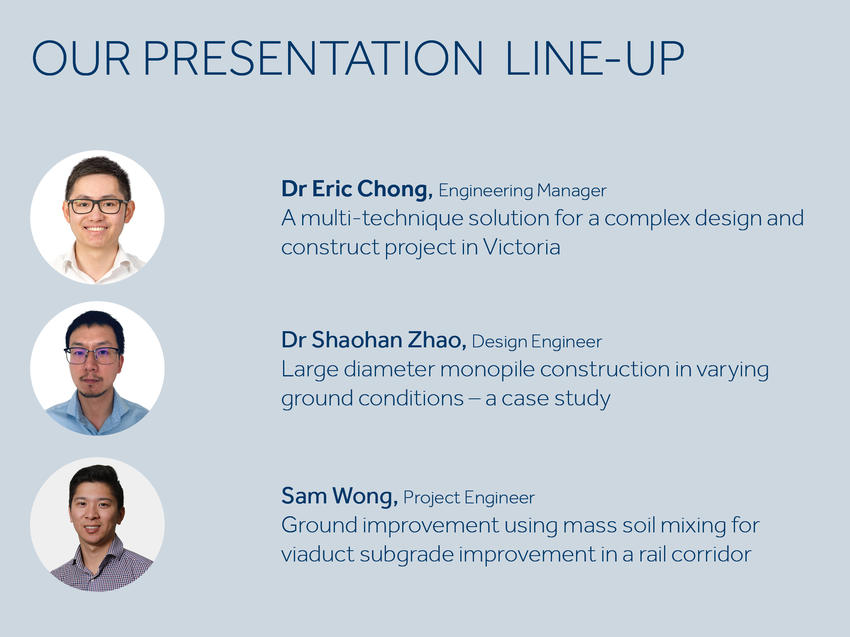

Eric Chong

Keller Australia, eric.chong@keller.com.au

ABSTRACT: A high-rise development consisting of residential and commercial uses has been proposed in Southbank Victoria where the site is relatively small with physical restrictions posed by the proximity to adjoining properties and an existing substation. The project required a retention system in soft/loose soils with a high groundwater table for a deep core excavation directly next to sensitive neighbouring structures and foundation piling for the structural loads. The design and construction of the retention system was complicated due to a tight deflection criterion imposed, the presence of the soft soils and construction tolerances of only 20mm to the adjacent building’s wall. A multi-technique solution comprising sheet piling, soldier piles, wet mass soil mixing (MSM) and an innovative construction method have been developed to meet the project specifications and safety requirements. The paper also describes the formulation of the foundation solution for the main works and how the continuous flight auger (CFA) piling technique was chosen as the preferred method to overcome the complex geotechnical risks encountered involving soft clays, a basalt tongue and a deep bedrock. The paper also explains how some the piles affected by the substation were redesigned and converted to driven precast piles due to physical restrictions.

KEYWORDS: sheet piles, mass soil mixing, ground improvement, deep CFA piling and driven precast piles

Ground improvement using mass soil mixing for viaduct subgrade improvement in a rail corridor

Samuel Wong, Eric Chong & Cliff Taylor

Civil Engineer, Keller, Australia, sam.wong@keller.com.au

ABSTRACT: This paper presents a case study on utilising the mass mixing (MSM) ground improvement technique for viaduct and enabling works on the Hallam Level Crossing Removal project completed in Victoria, Australia. MSM was adopted as the preferred solution to stabilise the soft alluvial deposits directly below the viaduct embankments by limiting settlements within these layers. The project involved the treatment of over 8,800m3 of soil. The paper details the formulation of field trials completed prior to the main works to verify preliminary design assumptions and calibrate appropriate mixing parameters to meet the design characteristic strengths and stiffness.

In what is believed to be the first application of MSM within a rail corridor in Victoria, the project encountered several challenges, including tight spatial constraints. working in a live rail corridor with the added complexities of operating within a COVID environment. The successful completion of the project demonstrates that MSM is a safe, cost-effective and efficient solution that can be performed in challenging conditions. Detailed discussions on the design, construction processes, results and lessons learned from MSM within a rail corridor will be covered in this paper.

KEYWORDS: Mass soil mixing, ground improvement and rail corridor

Large diameter monopile construction in varying ground conditions – a case study

Shaohan Zhao & Eric Chong

Keller Australia Pty Ltd, Australia, Shaohan.Zhao@keller.com

ABSTRACT: This paper presents the planning and construction of a foundation system with monopiles of 2.1m diameter for a level crossing removal project in Melbourne northeast. The piles were constructed with rock sockets in the Silurian age siltstone bedrock under a high groundwater table. Geotechnical investigations carried out indicated varying soil conditions and weathered brecciated siltstone/sandstone/basalt with dyke layers. These factors were considered together with the logistical complexities of working in the railway corridor during the project planning. To ensure high pile quality to be achieved, techniques were applied to the construction of the piles, inspection of the shaft quality, and verification of the pile integrity. The key points of these methods were also elaborated including the use of temporary casing, polymer fluid, tremie pile recording, sonic-based shaft profiling (Koden) and low-strain pile integrity testing (PIT). The paper also discusses the review of the pile quality data which showed good performance of the drilling fluid in supporting the open holes, and subsequently verified by the Koden tests and concrete pouring records. Results demonstrated that the application of different construction techniques performed well in challenging ground conditions.

KEYWORDS: bored pile, shaft, Koden test, pile integrity test (PIT).