Low mobility (compaction) grouting involves the injection of a low slump, mortar grout to densify loose, granular soils and stabilise subsurface voids or sinkholes.

Common uses

Process

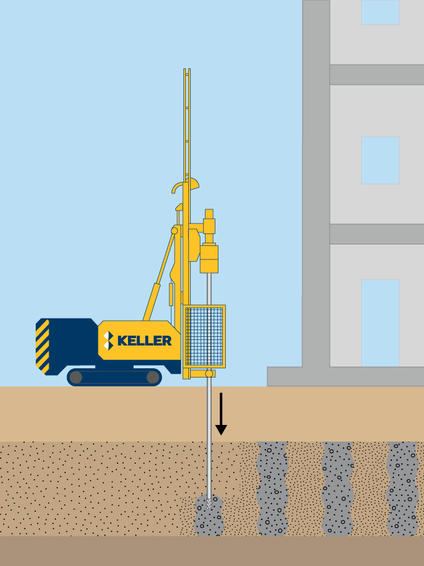

An injection pipe is inserted, typically to maximum treatment depth, and the grout then injected as the pipe is slowly removed in lifts, creating a column of overlapping grout bulbs. The expansion of the grout bulbs displaces surrounding soils and the grouting increases the density, friction angle, and stiffness of surrounding granular soils.

You can increase effectiveness by sequencing the compaction grouting from primary to secondary to tertiary locations. In all soils, the high modulus grout column reinforces the treatment zone.

Advantages

Quality assurance

Keller can provide complete solutions which combine compaction grouting with real-time monitoring of affected structures, and has a variety of rig types to accommodate access constraints.

Typically improvement is demonstrated by pre and post work in ground testing by CPT or DCP for example. Where possible a working verification section is incorporated into the start of the works to demonstrate and finesse the injection process.