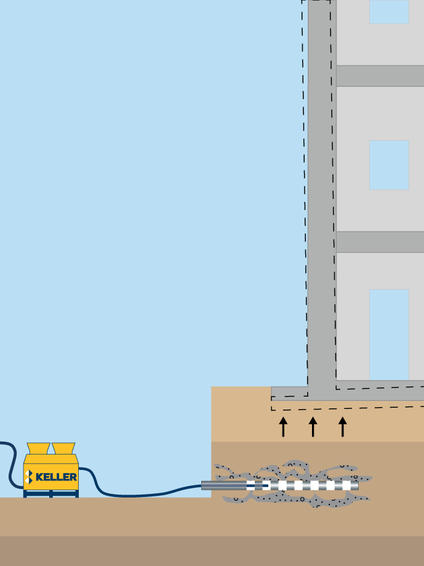

Compensation or fracture grouting is the injection of a cement slurry grout into the soil creating and filling fractures that can then be potentially used to lift the overlying soil and structures.

Common uses

Process

A sleeve port pipe (often referred to as a tube-a-manchette or TAM pipe) is grouted into a pre-drilled hole beneath a structure and grout injected under pressure at strategic locations through the ports.

Once the hydro-fracture pressure of the soil is exceeded, fractures open in the soil and are immediately expanded by the influx of grout. This results in the controlled lifting of the overlying soils and structures.

Advantages

Quality assurance

Keller can provide complete solutions which combine fracture grouting with real-time monitoring of affected structures.

Extensive experience has allowed us to develop advanced drilling and computerised grouting systems that integrate the grouting injection process and real time monitoring. Grout injection data is plotted against time and summarised in three dimensional plots and reports.