Wick drains, also known as Prefabricated Vertical Drains (PVD) are prefabricated geotextile filter-wrapped plastic strips with moulded channels. These act as drainage paths to take pore water out of soft compressible soil so it consolidates faster, often from decades to months.

Common uses

Process

The earthquake drain ground improvement method minimises bearing capacity failures and settlement during and immediately after a seismic event. It mitigates liquefaction using specially designed drains to limit excess pore pressures generated during seismic events to levels less than those that could trigger liquefaction.

Wick drains or PVDs consist of a prefabricated strip which is ideal for water transportation. The flexible core is typically manufactured of polypropylene and both sides have grooves allowing water to flow unimpeded. The core is wrapped in a strong and durable geotextile filter fabric with excellent filtration properties, allowing free access of pore water into the drain. This also prevents piping of fines from adjacent soils without clogging. Similarly, earthquake drains consist of corrugated, perforated pipes wrapped in a special non-woven, polypropylene filter fabric.

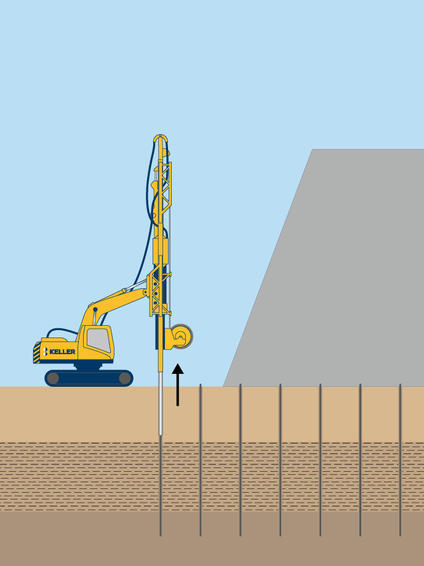

The drain is fed down through a hollow mandrel mounted on an excavator or crane mast, connected at the bottom to an expendable anchor plate. A vibratory hammer or static method is used to insert the mandrel to design depth. It’s then removed, leaving the wick drain in place. The wick drain is then cut at the ground surface, a new anchor plate connected to it, and the mandrel moved to the next location. A pattern of installed vertical wick drains provides short drainage paths for pore water, which accelerates the consolidation process and the construction schedule.

They are driven into the ground using a vibrating mandrel, consisting of a heavy-gauge steel pipe with three equally spaced fins to transfer vibrations to the adjacent soil. The vibrations result in densification of the granular soils, assisting in the liquefaction mitigation.

The earthquake drain is fed into the steel pipe, which is then driven into the ground down to treatment depth with the drain inside of it. The steel installation pipe is then vibrated back out. The end plate stays in the soil so that as the steel pipe comes out the earthquake drain stays in place.

The nominal 75mm (3 inches) diameter drain core is tightly wrapped with geotextile filter fabric (selected for its filtration properties), allowing free access of pore water into the drain, while preventing the piping of fines from adjacent soils. The geotextile wrap is very durable and able to withstand the handling and abrasion that occurs during installation. Several core designs and fabric types can be used to fit a variety of drainage applications and soil classifications.

Advantages

Quality assurance

We can ensure quality through:

- Automated data acquisition to record all installation parameters

- Trial area monitoring to prove design assumptions

- Surcharge monitoring