Rock grouting is normally done in fissured rock to reduce the flow of water along the joints and discontinuities in the rock.

Common uses

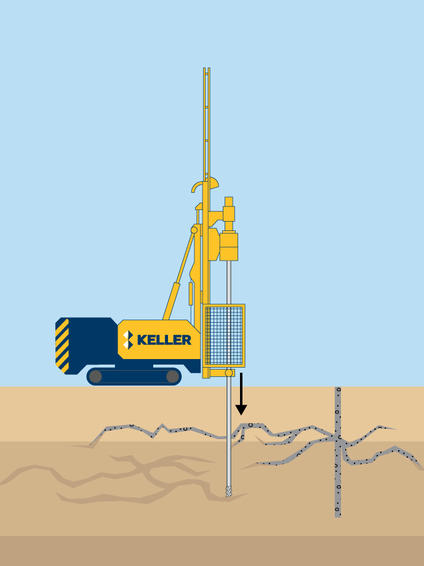

Process

Grout is typically injected in isolated stages from boreholes drilled using rotary percussive drills. Reduction in permeability is a function of the grouting material, the rock and grout design. Rock grouting is typically performed with general purpose, ultra-fine or micro-fine cement.

In practice, rock or fissure grouting, is implemented via one of two distinct methodologies: a traditional approach, whereby each injection commences with a higher mobility grout and is then progressively thickened during the injection based on pressure and volume parameters exhibited, and a method referred to as the ‘GIN’ or grout intensity number, whereby a single grout rheology is predominately used with more careful real-time computer controlled injections.

Advantages

Quality assurance

Keller has industry leading knowledge of grout materials and mixes and uses the latest drilling techniques to minimise borehole deviation and maximise efficiency.

We typically use computerised control and reporting of the grout injection process as we believe this provides the best customer outcomes in terms of achieving the required performance with the minimal injection of material. Importantly it also provides a tangible record of the process undertaken.